Scurrie Gets Major Upgrades for Franklin 2008

Scurrie performed pretty well at Motorama, but exposed a couple of big problems.

The first was the weakness of the drive gearboxes. The motors are powerful enough at 7.2 volts, and

the speed controllers can handle it, but the gearboxes aren't very sturdy. Many people actually said

a good hit in the beetle class had broken the same motors on their bots. I wanted to upgrade

to the next size up (the 36mm gearboxes) but didn't have any weight to spare. The other problem

was the ease with which the shaft could be bent on a big hit. I needed a better shaft solution.

Well, it was time to get serious on this bot and actually buy some components that were made for it

now that we had proven that it could work. The old batteries from 2003 were starting to struggle a

little by now and I decided it was time to replace them. A new kind of battery called the

A123 M1 Cell

had just come out. It boasted very high power-to-weight ratio, low weight, and a capacity that was well-suited

to 12 and 30 pound robots. The cells were a good fit between the volatile Lithium Polymer cells and much heavier

Nickel based chemistries.

I decided I would try to build a split-battery system, with 5 cells running the weapon and 2 cells running the drive

system. I could maybe have pushed it to 3 cells on the drive system but didn't know if 9.9 volts would be too much.

This battery layout would let me eliminate the extra 8oz battery pack from the bot, while weighing just under the weight

of the single 12 cell weapon pack I had before. The wiring would be more complicated, but the extra weight and space

would allow me to upgrade the drive gearboxes to the bigger versions.

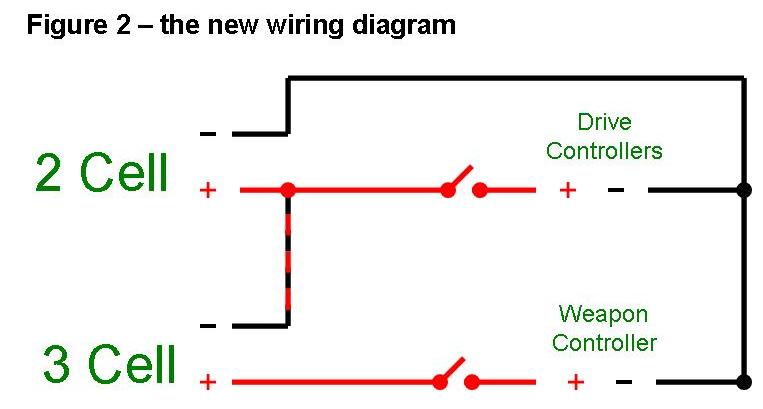

I later wrote an article for Servo magazine on how the battery system was created, but the simplest way to explain it is

this drawing. You can see that the system takes two switches because I wasn't sure whether my weapon controller

was opto-isolated. The two switches weren't too much of a pain, and it worked perfectly as long as I always turned

the drive switch on first. This allowed me to have a ~18v rail for the weapon and a ~7v rail for the drive without separate

batteries like the old version.

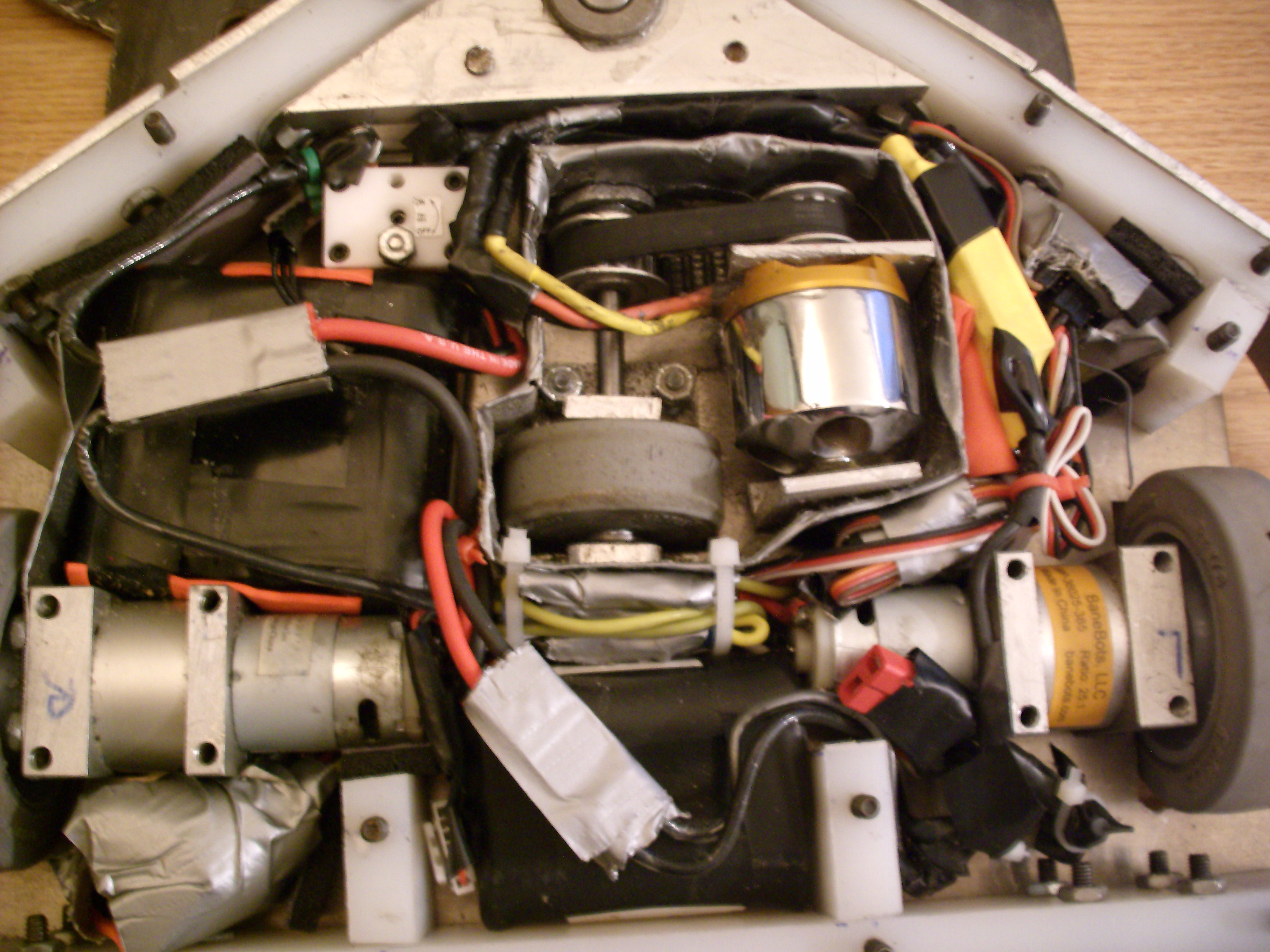

These are the upgrade internals of Scurrie. You can see the two flat A123 cell packs. The 2-cell is bottom-middle, and the

3-cell is middle-left. The bigger gearboxes are also installed. What you can't see in this picture very well is that

I added outbard bearing supports to the motors so the wheels are now double-hung. This takes much of the load off of

the gearboxes. This created a huge increase in reliability.

Also in this picture you can sorta see the improved weapon mount. It now spans the entire front of the bot to brace

both frame pieces. I added frame cross supports at the other corners too, to resist horizontal loads. This resulted in

a very strong frame.

I had a local machine shop turn a weapon shaft for me out of a single billet of 4130. The shaft

was then hardened to Rc40, which made it much, much stronger than the old one. Combine that with a

lower profile filet on the inside of the shaft because it was turned instead of welded and you get much

better support for the blade. I also had the blade hardened to Rc 35 to improve its stiffness. The guys

at Peters' Heat Treat did a great job, and actually

did it for free because I was a referee/judge at the Meadville robot competition, which they sponsor.

The outside of the bot was greatly improved as well. I added big looped wheel guards around the wheels

to fend of horizontal attacks by removing any sharp corners and providing a large air gap. This picture was

taken after the competition, and I think it held up great. It's amazing that the smaller and lighter

batteries could give me enough weight to coat the entire bot in aluminum as well.

Ok, now that I made you read all of that, here's a video overview of the changes. Sorry for the bad lighting!

Check out how the bot did at Franklin Institute 2008.